Based in Mississauga, ON, Cap-Thin Molds is a mold injection company that manufactures high-quality molds and cost-effective packaging solutions for injection molded plastic products in packaging, caps and closures for cosmetics, food, medical and thin wall containers. With a 30+ year history we are backed by our extensive experience and knowledge in the industry. Our mold manufacturing experts are committed to helping our clients with their needs. We’re confident that our mold injection company can meet or exceed your expectations.

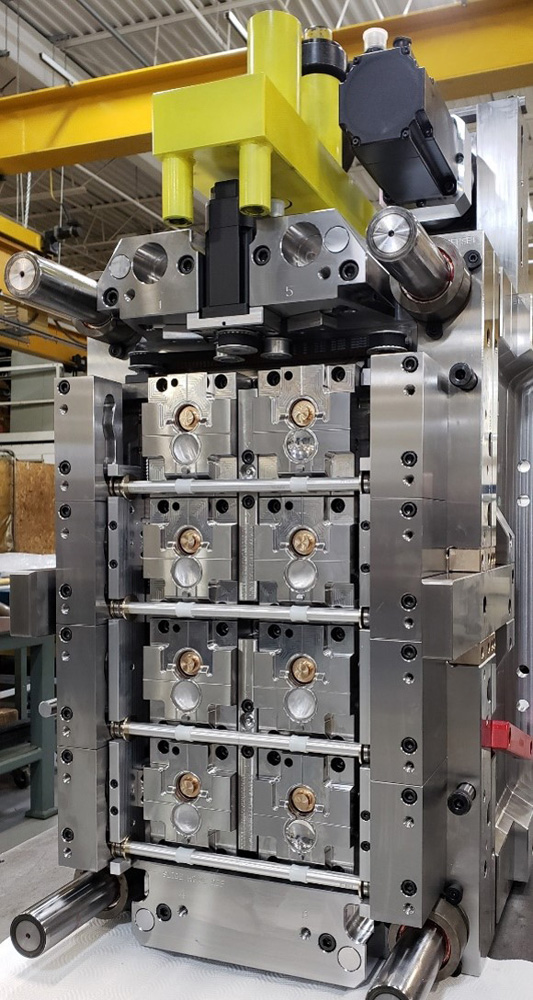

Our niche is with molds up to 96 cavities and 500 machine size tons.

Mold design and engineering is a unique process for each and every product. Our 5 expert mold design engineers review and analyze even the smallest aspects of a product, assuring the production of only the highest-quality, well-designed and properly engineered molds. Filling analysis is available through a 3rd party. Our molds are engineered in 3D with Creo & Solid Works software, full detailed for full interchangeability. Design review meetings are conducted using 2D & 3D models. These meetings are often held remotely, using a web-based conferencing software. This keeps our customers updated while reducing their travel costs.

Our team in continuously working on the advancement of our capabilities and improving our know-how and techniques for plastic injection molded products of the 21st century. Through research and development we are able to manufacture high quality production molds that are extremely efficient and reliable. Reducing cycle time, power consumption, average wall thickness, new molding methods and processing, it has directly resulted in improving the quality of our molds and reducing costs for you.

Cap-Thin Molds has invested in itself to be a state-of-the-art mold-manufacturing facility that is climate controlled and cyber secure. We are equipped with:

Our team can support all of your inquiries. We can help you with more than just quoting. Whether you need help with product design advice, on a new mold or improvement of an existing design, all of those questions are easily answered by the professionals at Cap-Thin Molds. We’re happy to support you with system configurations:

Our expertise and knowledge with hot runner systems allows us to determine configurations and:

The three machines we use for mold testing are a 150-, 350-, and 450-ton Athene machine and we can provide you with:

Cap-Thin Molds teams are led by a Project Management Professionals to ensure that best practices for managing projects is applied with:

We are focused on developing long term relationships and customer intimacy. We want to attain a full understanding of your business to give us an implicit understanding of your needs, and not waste your time with communication errors.

With our expertise and knowledge we focus on solving your complex situations, share our real life examples enabling us to exceed all of your expectations and requirements and ensure you are profitable!

We keep our customers on the leading edge of technology, and will make cycle time guarantees and back them up in writing.

Is your mold running as efficiently as it did when it was new? Getting the most out of your tooling is a priority, We will work with your production team to thoroughly plan the refurbishment process to minimize downtime.

We have the capability to reverse engineer the mold to regenerate missing drawings and data.

We provide fully tested molds ready to run in your facility and refurbishment services.

Are you experiencing high scrap rates from your mold? Is your mold running as efficiently as it did when it was new? See what money can be saved by contacting Cap-Thin Molds today by phone or email. We’d love to discuss with you how you can benefit from our mold injection services. We look forward to being of service to you soon!

940 Meyerside Dr

Mississauga, ON L5T 1R9

We offer our services in Canada.